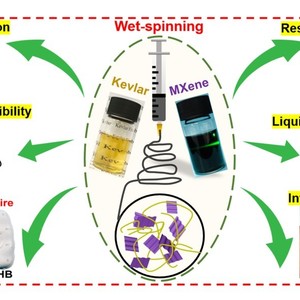

Scalable Fabrication of Kevlar/Ti3C2Tx MXene Intelligent Wearable Fabrics with Multiple Sensory Capabilities

Citation

Baochang Cheng, and Peiyi Wu*. Scalable Fabrication of Kevlar/Ti3C2Tx Mxene Intelligent Wearable Fabrics with Multiple Sensory Capabilities. ACS Nano 2021, 15, 8676.

Abstract

Fiber-based wearable electronics are highly desirable for wearable devices that are expected to be lightweight, easily prepared, durable, flexible, washable, and conformable. However, developing fiber-based fabric electronics to simulate human perceptual systems or even transcend the sensory capabilities of natural creatures is still a pivotal challenge. Herein, we present a Kevlar/MXene (KM) intelligent wearable fabric with multiple sensory capabilities using an ingenious strategy of continuous wet-spinning. The KM fibers can be washed, knitted, sewed, and fabricated into smart KM fabric sensory systems. An intelligent KM sensory mask is prepared to monitor human breathing in time to detect respiratory problems with high accuracy and portability. It provides an important reference for judging diseases and achieving remote diagnosis. Additionally, a smart temperature-responsive sensory glove is developed to help people make proper behavioral prejudgments and prevent potential injuries by sensing surrounding hazards beforehand. Moreover, this sensory system allows soft robotics to make a rough identification about the basic properties of unknown liquid molecules. Overall, by the virtue of the ultrafast responsiveness (90 ms), resilience (110 ms), and ultrasensitive capability in pressure responding, this KM sensory system offers a gentle approach for wireless detection in information encryption, transmission, and preservation by touching the sensory system with variable pressing time on the basis of the International Morse code principles, establishing a competitive and promising candidate for next generation wearable flexible fabric electronics.